Features of UV laser printing

The surface of the tablet or capsule is irradiated with a UV laser to change the color of the titanium dioxide content to gray for printing.

The non-thermal effect of the UV laser makes it possible to print on tablets and capsules without causing thermal denaturation.

Mechanism of UV laser printing 1

How to print on tablets?

The main feature of UV laser printers is that they print without using ink.

This section explains the printing mechanism and how printing is done.

Overview / Mechanism of UV laser printing

The surface of solid preparations (tablets and soft capsules) is irradiated with a UV laser to change the color of the titanium dioxide content to gray for printing.

Due to the non-thermal effect of the UV laser, printing is possible without causing thermal denaturation of the solid formulation.

Mechanism of UV laser printing 2

How UV lasers can print

The surface of solid preparations (tablets and soft capsules) is irradiated with a UV laser to change the color of the titanium dioxide contained in the material to gray for marking.

Due to the non-thermal effect of the UV laser, printing is possible without causing thermal denaturation of the solid formulation.

The UV laser generated by the UV laser oscillator passes through mirrors and lenses to print on the target surface.

What is the process for UV laser printing?

Titanium dioxide has a stoichiometric ratio of titanium (Ti) to oxygen (O) of 1:2, except in cases where the manufacturing conditions result in oxygen-deficient crystals with insufficient oxygen (O).

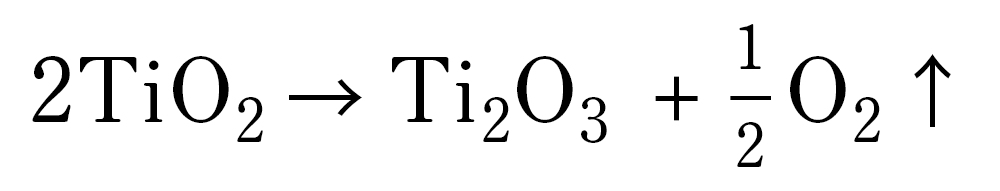

UV laser irradiation causes the oxygen to desorb from the crystal as shown in the following equation.

Source:

・M. E. Straumanis. T. Ejima and W. J. James. The Ti02 Phase Explored by the Lattice Constant and Density Method. Acta

Cryst. 14. 493-497 (1961).

・W.A.Weyl and Tormod Förland. Photochemistry of rutile. I. & E. C. 42, 257-263 (1950).

・Koichi SASAKI,etal., J. Jpn. Soc. Pharm. Mach. & Eng.; 18(1)5-14(2009)

Advantages of UV Laser Printing

Printing is performed by irradiating the tablets with a UV laser.

This printing method offers both freedom of design and a significant reduction in running costs.