Advantages of UV Laser Printing

UV laser printing is a relatively new method of tablet printing.

The main features of UV laser printing are that it does not require ink and has a very low defect rate, among many other benefits.

Let’s take a look at the benefits of UV laser printing and what it has to offer that other printing methods do not.

No heat damage

The surface of solid preparations (tablets and soft capsules) is irradiated with a laser in the ultraviolet region of 355nm, causing the titanium dioxide to change color to gray.

Since there is no thermal damage, it does not affect the medicinal ingredients.

In addition, once printed, the color is difficult to fade.

No printing ink required for easy maintenance

Unlike other printing methods, no ink is required because the marking is done by UV laser.

This eliminates the need for ink replenishment and cleaning, shortening the time required for item changeover in factory production and improving production efficiency.

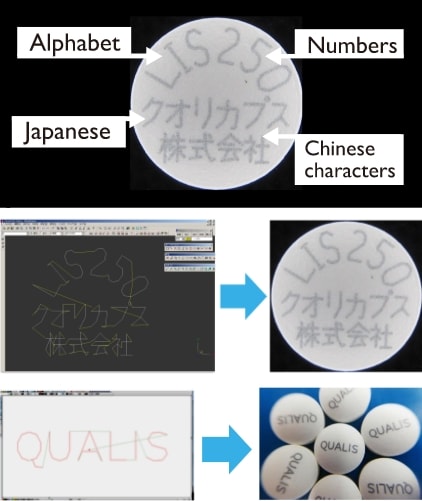

Flexible design and wide printing range

Offset printing requires the creation of a master plate based on electronic data.

However, with UV laser printing and inkjet printing, electronic data can be directly reflected in the printing process, reducing the time required to create the original plate.

It is also easy to change the printing design.

Sufficient productivity

In general, offset printing is said to have the highest throughput.

However, UV laser printing is close to processing capacity of offset printing.

Almost no printing defects! High yield rate

Less than 0.01%* of printing defects are caused by UV laser printing!

Since no ink is used, printing defects such as missing characters, double printing and ink transfer (smearing) do not occur.

Since there are far fewer printing errors, production is more efficient and waste can be reduced.

(*Source: Koichi SASAKI,etal., J. Jpn. Soc. Pharm. Mach. & Eng.; 18(1)5-14(2009))

No running costs

Offset printing requires an intaglio plate called a design roll for each printed design, but UV laser printing does not require a design roll because the printed design is created electronically.

UV laser printing saves space and reduces running costs by eliminating the need to recreate design rolls and ink.

Halal Support

In general, printing ink may contain alcohol or animal ingredients.

With UV laser printing, no ink is used, so there is no need to worry about the ingredients contained, and Halal compliance is possible.

Therefore, those who have reasons related to religious doctrines or beliefs can take printed tablets/capsules with peace of mind.

Environmentally friendly

There are no harmful emissions from the equipment.

It also meets the regulations of the Ministry of Health, Labor and Welfare for occupational safety during operation.

It is environmentally friendly due to the elimination of organic solvents, and contributes to ISO 14000.

(ISO 14000 is the collective name for the international standards for environmental management systems issued by the International Organization for Standardization (ISO), the most widely used organization in the world.)