Features of the CO2 laser

The surface of the tablet or capsule is iThere are several methods of printing for formulations, and one of them is laser printing. There are two types of laser printing, one using a UV laser and the other using a CO2 laser. These two lasers have different characteristics. CO2 laser printing is mainly used for printing soft capsules in pharmaceutical and health food products because of its high visibility even on transparent capsules. This page provides basic information about CO2 lasers and how they print.

Basic information on CO2 lasers and how they work for printing

What is a CO2 laser?

A CO2 laser is a type of gas laser that uses carbon dioxide (CO₂) as the laser medium, and can process the irradiated object by applying heat to it. It is the most widely used laser technology in laser processing machines, and is suitable for processing transparent materials such as wood, acrylic, and glass. In addition to printing, CO2 lasers are also used for drilling, gate-cutting, half-cutting, and other processing applications because they apply heat to the object. In the pharmaceutical and health food industries, it is often used for printing soft capsules.

How capsule printing works

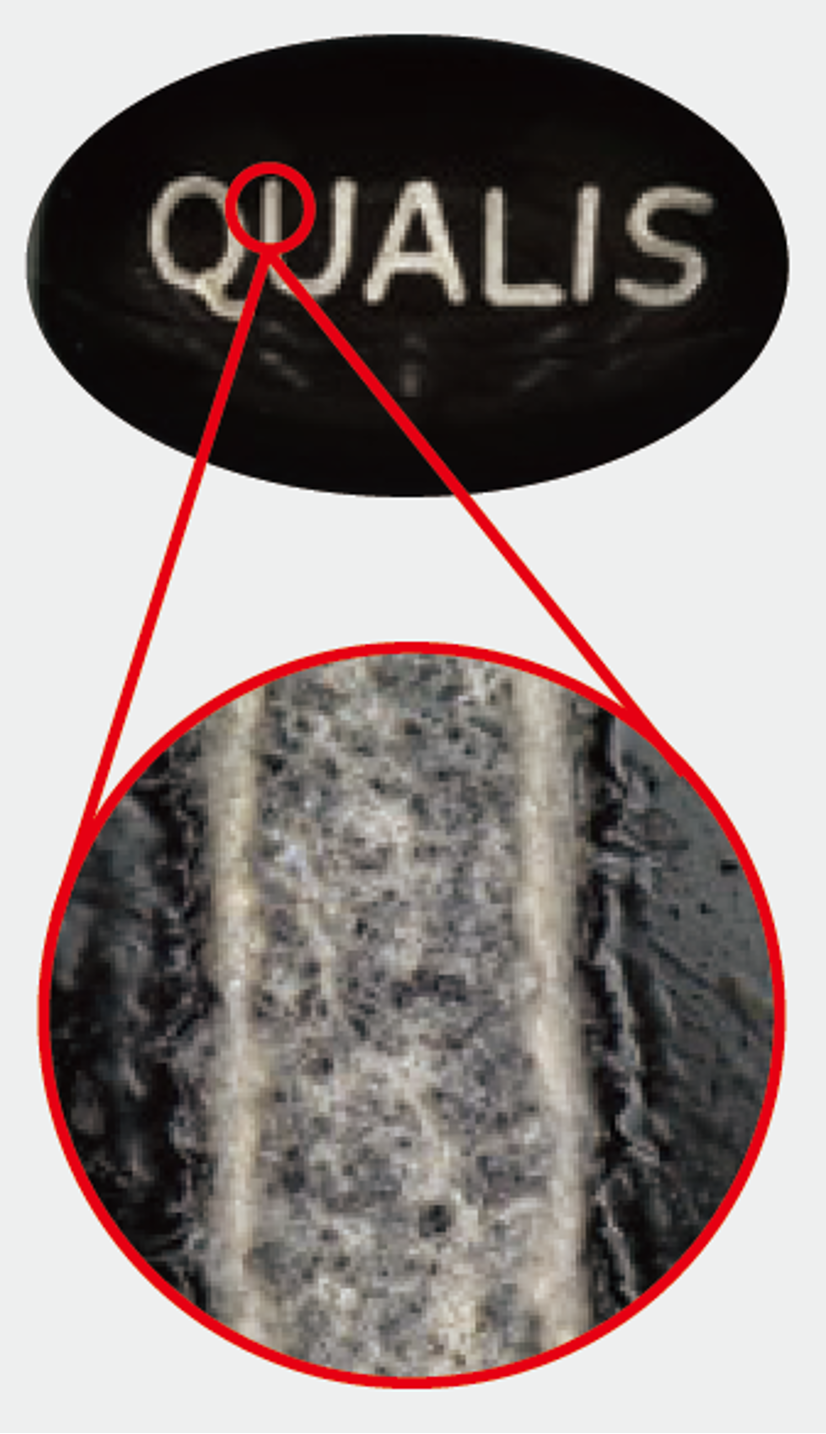

When the capsule is irradiated, the water contained in the capsule film vaporizes and bubbles are generated on the capsule surface. The area where the bubbles are generated turns white, and characters and figures are printed. Another feature of CO2 laser printing is that it is highly visible even on transparent capsules.

How to produce an infrared laser beam?

The CO2 laser (carbon dioxide laser) is a molecular gas laser with emission in the long-wavelength infrared spectral region and produces a beam of infrared light with the principal wavelength bands centering on 9.6 and 10.6 micrometers (µm).

The most basic form of a CO2 laser consists of a gas discharge with a total reflector at one end, an output coupler (a partially reflecting mirror) at the output end, CO2 gas filled tube and electrode plates for a discharge. A discharge produced plasma light is generated and the light is amplified as it travels back and forth between the total reflection mirror at one end and the output coupler (a partially reflecting mirror) at the output end., and is output as a laser.

Advantages of CO2 Laser Printing

This is a method of printing by irradiating the capsule with a CO2 laser. It is often used for printing soft capsules because of its high visibility even when the printed surface is transparent. It is also one of the most cost-effective printing methods as it does not require ink.